Gap Dimension Governs Air Wipe Performance

Air Wipes

Bow Guides

Eyelet Guides

Nozzle Guides

Pulleys

Ring Guides

Rods

Roller Guides

Snail Guides

Tube Guides

U- Guides

Welding Butts

Surface Finish

Glossary

Inquiry Forms

Materials

Site Map

As shown in Supersonic Air Wipe , the AWM 51 - 1.4 Performance Data Sheet registered Supersonic Air Flow at a gap of 0.1 mm. But what about gap dimensions other than 0.1 mm? Lab tests revealed that air velocity is inversely proportional to gap dimension.

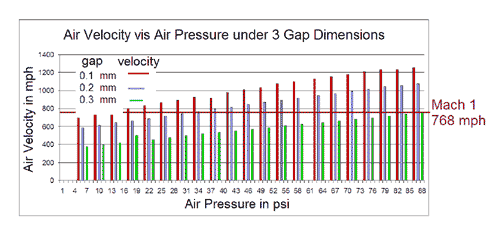

The chart below demonstrates the relationship between the air velocity and air pressure at different gaps. Here the air gap (or gap) is defined as the space between either side of the wire and the wall of the wiping cylinder as the wire passes through an air wipe. For example, when a wire of Ø 1.2 mm goes through a wiping cylinder of bore Ø 1.4 mm, the gap is 0.10 mm.

In the above chart, air velocity within the wiping cylinder was measured at 21 ascending pressure settings from 6 to 86 psi. Three (3) velocities were registered under gaps 0.1, 0.2, and 0.3 mm respectively at each pressure setting. It can be seen that at each setting the air velocity is higher with the smaller gaps. For instance, at an air pressure of 40 psi, the air velocities were, respectively

mph gap (mm)

950 0.10

800 0.20

560 0.30

By comparison, the air velocity drops by an average amount of 41% when the gap increases from 0.10 mm to

0.30 mm. However, since K. E. = 1/2 M V 2, the Kinetic Energy in the wiping cylinder was reduced by half. The analysis validated that a narrow gap is crucial to the optimum performance of an air wipe.

The lower limit of the gap

The narrowest permissible gap with our air wipes is 0.10 mm*. It has been registered that as the gap narrows below 0.10 mm, the air velocity started to decline from its peak, presumably due to friction and/or turbulence. Furthermore, in choosing the appropriate wiping cylinder bore diameter to maintain the optimum gap, please always take into account the manufacturing tolerance of the wire.

The manufacturing tolerance of the wire

Wire, like all fabricated products, are subject to manufacturing tolerances which for a wire of nominal diameter of

2.5 mm can exceed 0.1 mm in the upper spec and if neglected, may cause wire jamming. With fine gage wires, this is less of a problem.

* There is an exception. In Replacement Air Wipe AW 5, the gap can be as narrow as 0.025 mm, due to the

short wiping distance of less than 1 mm.

Home Supersonic Air Wipe AWM 51 AWM 61

Replacement Air Wipe Vortex and Evidence How to Save Air Wiping Cost